Electromagnetic Flow Meter

Fluido's magnetic flow meter, also known as electromagnetic flow meter or mag meter, is widely used as it has less obstruction, cost effective and gives accurate measurement. Electromagnetic flow meters don't have any moving parts to wear own, reduciing the need for maintenance or replacement. we offer flow meters with a range of liners, electrodes, and sizes, which can meet various conductive liquids.

Application

- Effluent Treatment Plant

- Textile Processing Industries

- Sugar Industries

- Steel and Aluminium Industries

- Food and Drug Industries

- Dairy Industries

- Sewage Treatment Plant Water Supply Scheme

- Chemical Industries

Benefits

- Wide range of nominal diameters (15 NB-600 NB)

- Independent of pressure, temperature, density and viscosity

- No moving part, maintenance-free

- Automatic power failure recirding function(optional)

- Built-in grounding electrodes

- Bi-directional flow measurement

- High accuracy 0.5% available

- Self-diagnosis function, empty pipe alarm, exciting alarm

- Support data record/ wireless communication

PRODUCT PERFORMANCE AND SPECIFICATION

| Size | NB 15 - NB 600 (1/4"-24") | |

|---|---|---|

| Accuracy | ±0.5% of reading at flow velocity ≥ 0.5m/s | |

| Velocity | 0.1-15 m / s | |

| Repeatability | ≤0.17% | |

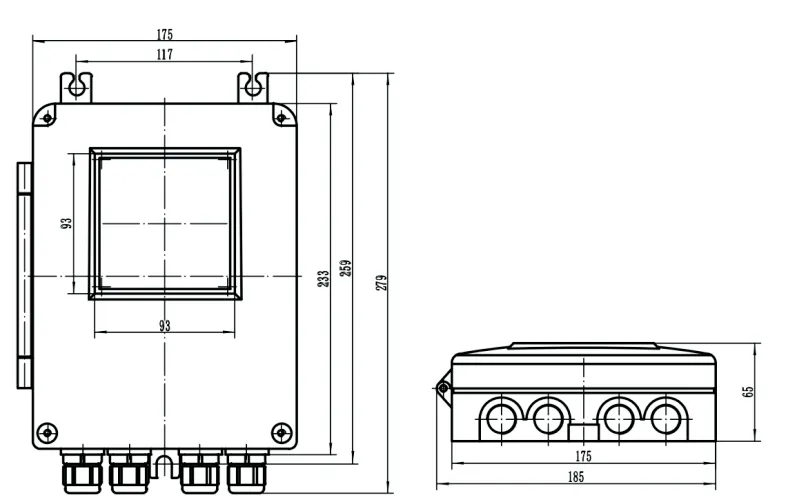

| Structure | Integral / remote , cable length 10m standard , 100m max | |

| Conductivity | > 5 µS / cm , demineralized water > 20 µS / cm | |

| Protection Grade | Transmitter : IP65 standard , IP67 optional Sensor : IP65 standard , IP68 ( submersible , only available for remote type ) |

|

| Electrode | SS316L , Hastelloy C , Titanium , Tantalum , | |

| Power Supply | 85 ~ 250 VAC ( 50/60 Hz ) , 20 ~ 36 VDC | |

| Power Consumption | < 20W | |

| Signal Output | Analog | 4-20mA ( load resistor 0-7500 ) |

| Frequency | Forward & reverse flow output with a frequency range of 1-5000Hz | |

| Alarm | Two isolated open collector transistor ( OCT ) outputs for alarm signals | |

| Communication | RS485 MODBUS RTU standard , HART , GPRS , PROFIBUS optional | |

| Display | LCD Display 128x128mm , three lines , 4 buttons | |

| Ambient Temperature | -20 ° C - 60 ° C | |

| Fluid Temperature | Compact : -20 ° C - 80 ° C , Remote : -20 ° C - 120 ° C | |

| Liner Material | PTFE ( -20 ° C - 150 ° C , 15 NB TO 300 NB ) Hard Rubber ( -10 ° C - 80 ° C , 50 NB TO 600 NB ) |

|

| Flange Standard | ANSI | |

| Sensor Material | Measuring tube : SS304 Flange 6 housing : carbon steel ( standard ) , SS304 / SS316 optional |

|

| Transmitter Material | Aluminium alloy with epoxy painting | |

| Nominal Pressure | 150 # / 300 # / ANSI | |

| Display | Instantaneous flow , total flow , flow velocity | |

| Function | High and low alarm , exciting alarm , empty pipe alarm , self - diagnosis | |

| Totalizer | Three built - in totalizers : forward flow , reverse flow and net flow | |

| Display Unit | L / s , L / m , L / h , m3 / s , m3 / m , m3 / h , kg / s , kg / m , kg / h , t / s . t / m , t / h | |

| Language | English | |

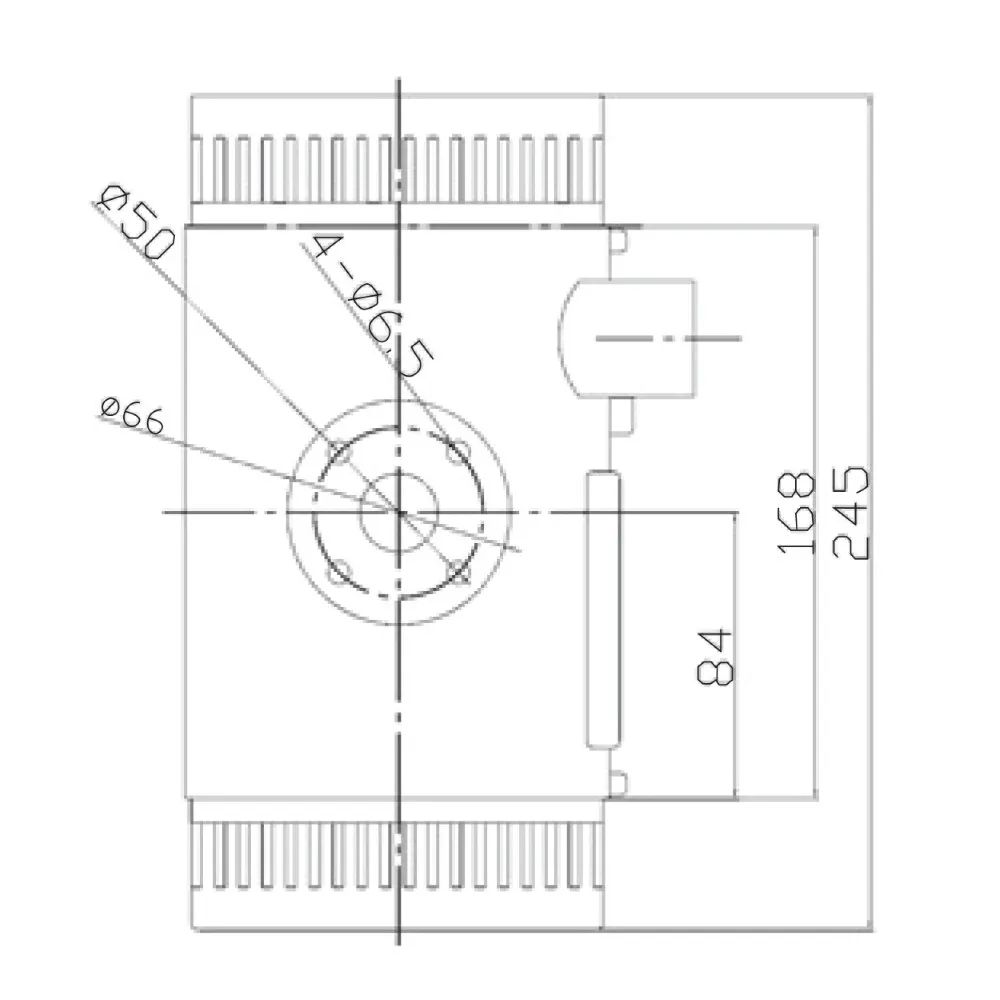

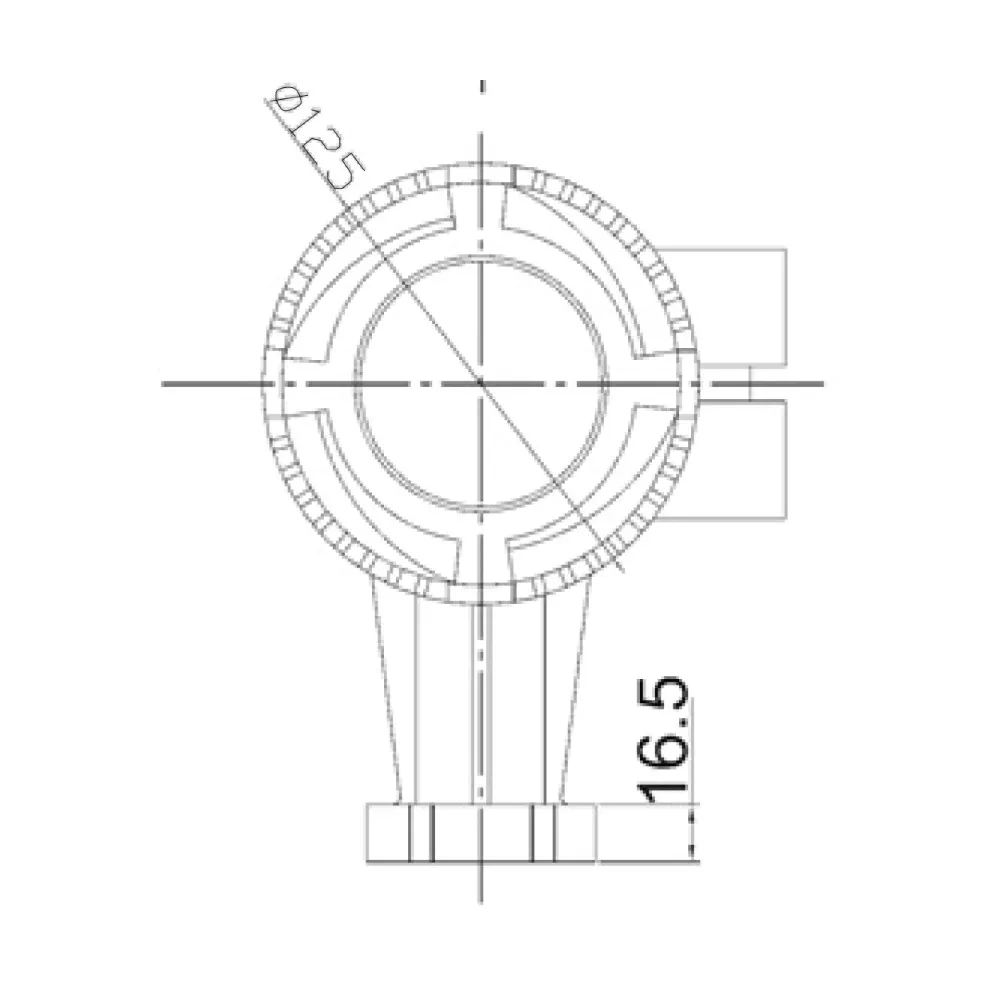

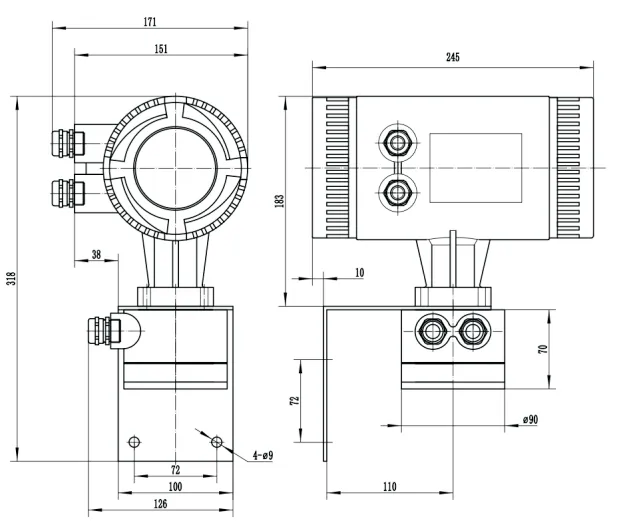

TRANSMITTER DRAWING

PERFORMANCE OF ELECTRODE MATERIAL

| Electrode Material | Application |

|---|---|

| SS 316 L | Applicable to industrial and municipal water, wastewater and low corrosive mediums. Widey used in petroleum, chemical industries |

| Hastelloy C | Exceptional resistance to strong solutions of oxidizing salts and acids, like Fe+++, Cu++, Nitric acids, mixed acids. |

| Titanium | Titanium can withstand corrosive medium such as seawater, chloride salt solutions, hypochlorite salts, oxidable acids (including fuming nitric acids), organic acids, and alkali. not resistant to high purity reducing acids such as sulphuric acids, hydrochloride acids. |

| Tantalum | Highly resistant to corrosive mediums . Applicable to all chemical mediums except Hydrofluroic Acids, petroleum and Alkali. |

PERFORMANCE OF LINEAR MATERIAL

| Linear Material | Application |

|---|---|

| PTFE | Best Performance of linear material, chemical resistance, withstand boiling hydrochloric acid, sulphuric acid, nitric acid,alkali and vareity of organic solvents. Poor wear resistance and poor adhesion. |

| Hard Rubber | Withstand the corrosion of hydrochloric acid, acetic acid, oxalic acid, ammonia water, phosphoric acid and 50% sulphuric acid,, sodium hydroxide, potassium hydroxide. Use of general acid, alkali, and salt solutions, not resistant to the corrosion of strong oxidants. |